Dewatering Screens have a wide variety of applications, including dewatering, desliming, degritting, rinsing, scrubbing, sizing and washing. They are designed to produce a consistent drip-free product and handle materials such as sand, gravel, crushed aggregates, frac sand, industrial sands, mineral sands, hard rock, precious metals ore, coal, iron ore, salt and other granular materials, according to McLanahan Corp.

Surface moisture as low as 7% has been achieved with McLanahan Dewatering Screens; however, final moisture is dependent on surface area, surface morphology and contact angle. Finer materials, such as those processed in fines recovery systems where the material is 100% passing 100 mesh (150 µm), will dewater to a drip-free consistency, which conveys and stacks, but may have a surface moisture content >20%.

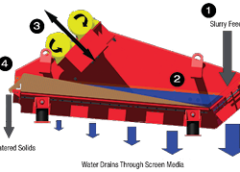

To dewater material effectively, slurry is fed onto a steep, downward inclined screen surface at the feed end of the Dewatering Screen to achieve rapid drainage. A pool of water begin forms in the valley as material builds up on the slightly upward inclined surface. Counter-rotating vibratory motors (or mechanical exciters on the largest of Dewatering Screens) create a linear motion at an angle to the screen surface that accelerates the solids upward and forward at 5G. This, along with a generous stroke length, moves water through the countless openings between the particles to promote droplet formation.

The abrupt reversal of motion detaches water from the material, and the water droplets pass through the screen media. The solids are conveyed up the screen by this linear motion. The uphill slope of the screen, along with a discharge weir, creates a deep bed that acts as a filter medium, allowing retention of material much finer than the screen openings. A thick bed of material promotes fine retention while allowing the water to migrate through.

Where cleaner materials are required, cross dams and spray bars can be included to assist with the washing process, liberating fines that pass through the media. Using a dilute feed and additional spray water, these screens can affect some limited sizing. Dewatering Screens can be used for limited efficiency fine sizing at or above 10 mesh (2 mm) to create differential products, for stone washing and rinsing <2-in. (-50 mm) aggregates prior to loadout, desliming, and for trash/organics dewatering/screening.

McLanahan Corp., www.McLanahan.com